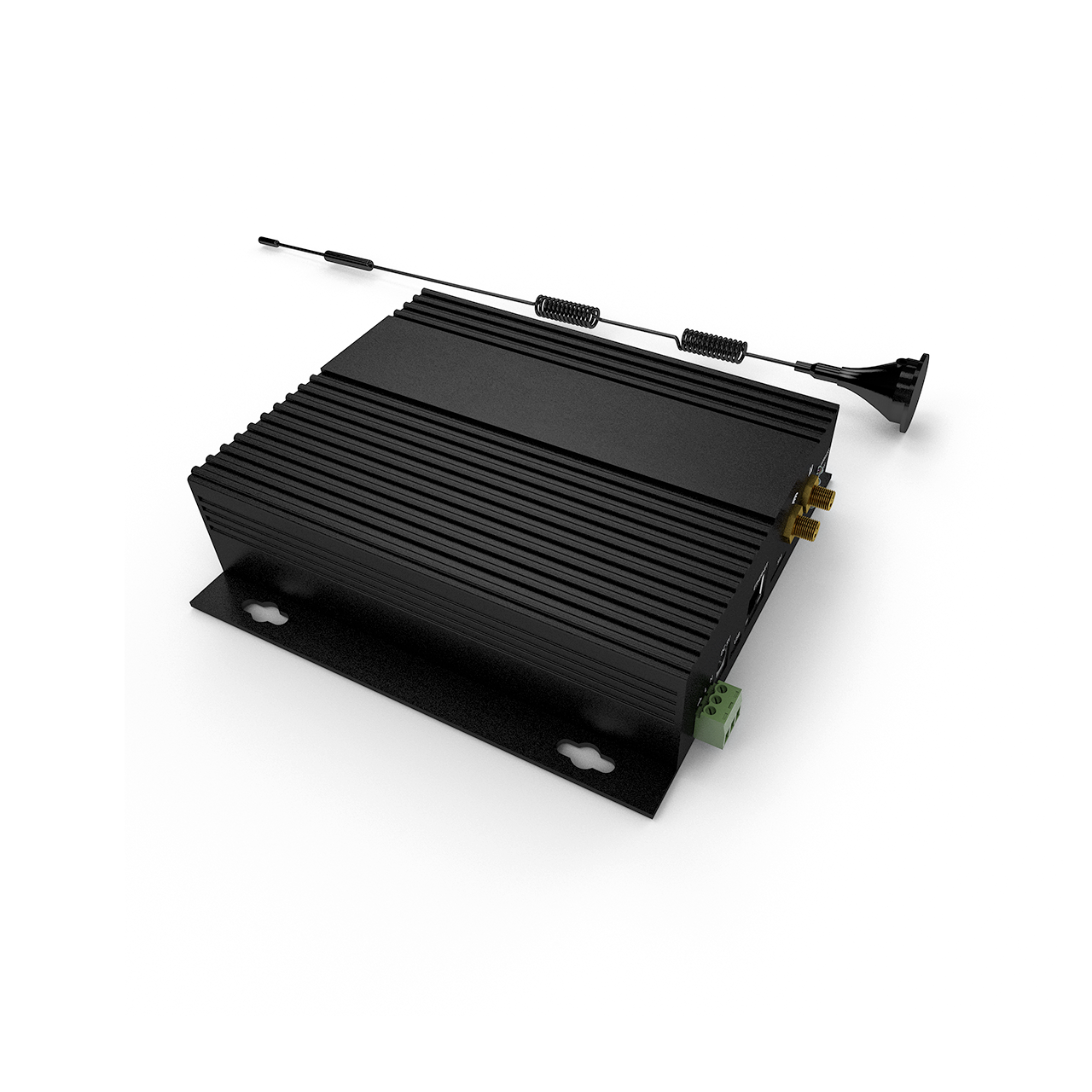

controller

This is a universal controller for the Internet of Things that can address most common automation control, sensor detection, and other needs.

It can replace or even complete tasks that PLC cannot complete, and achieve flexible ultra-high degree of freedom management through online programming and configuration. Developers can write and modify business logic online without rushing to the site.

Easily respond to various industrial and agricultural needs.

Feature

Power supply method

The controller retains wired power supply (220V AC power supply, 5V charger) and networking (Ethernet). At the same time, it can choose 3.7v lithium battery with solar panel power supply (fully charged and can work for 48 hours), and choose WIFI or 4G module networking. This way, the controller can break free from the limitations of wires and network cables and be flexibly arranged in any position.

Charging method

The controller supports RS485 communication and can connect to the vast majority of sensors on the market (directly or indirectly), making it convenient for users to access third-party sensing units. The controller is equipped with 16 sets of IO interfaces, which meet the control needs of the vast majority of devices on the market by controlling relays or directly controlling terminal devices.

Modularization

The controller can control all connected terminal devices and change the control logic through online programming to achieve more professional control. For example, the controller is connected to 15 sensing units (air temperature, RH, solar radiation, photosynthetic active radiation, CO2 concentration, leaf temperature, soil temperature, soil moisture content, soil conductivity, etc.), as well as 10 terminal devices (shading net, air outlet motor, cotton quilt, humidification device, heating device, LED light supplement, water fertilizer machine, etc.). Users can write a program online, Control any one of the 10 terminal devices based on linkage of any one or N readings from 15 sensing units. Only one controller is required, and users can flexibly change the correspondence between sensors and terminal devices by editing scripts online (providing guidance), or adjust the logical functions of existing relationships, rather than just changing the size of input parameters.

Reviews

There are no reviews yet.